As you search for an ideal power unit to serve your facility, several questions come to mind as you consider your options. Where would you place the unit? What voltage would best suit your operations?

While many facility owners have checklists of what they want in an industrial generator, they seldom think about how this robust equipment functions to distribute energy throughout their property.

Generators are complex machines with many moving components that work together to produce electricity. In this article, you’ll discover how industrial generators create electricity and how each part plays a role in ensuring maximum power output.

How Do Generators Produce Electricity?

Contrary to popular belief, an industrial generator cannot actually manufacture electricity. While it sounds surprising at first, allow us to explain! Via a scientific principle called electromagnetic induction, industrial power generators can convert chemical or mechanical energy into electrical energy.

The process occurs by using the power of motion to transfer electrons from an external source through electrical circuits that can transform particles into electrical energy. Essentially, the generator is an electrical motor that works in reverse to provide enormous amounts of power in different applications.

Fun Fact

The electromagnetic induction principle is thanks to English physicist Michael Faraday. Faraday discovered electromagnetic induction around 1832. The physicist recognized that he could induce the flow of electrical charges by moving a conductor.

At the time, his conductor was a wire containing charges housed in a magnetic field. The movements produced created a voltage difference between both ends of the conductor, causing a steady flow of electrical charges and generating a current.

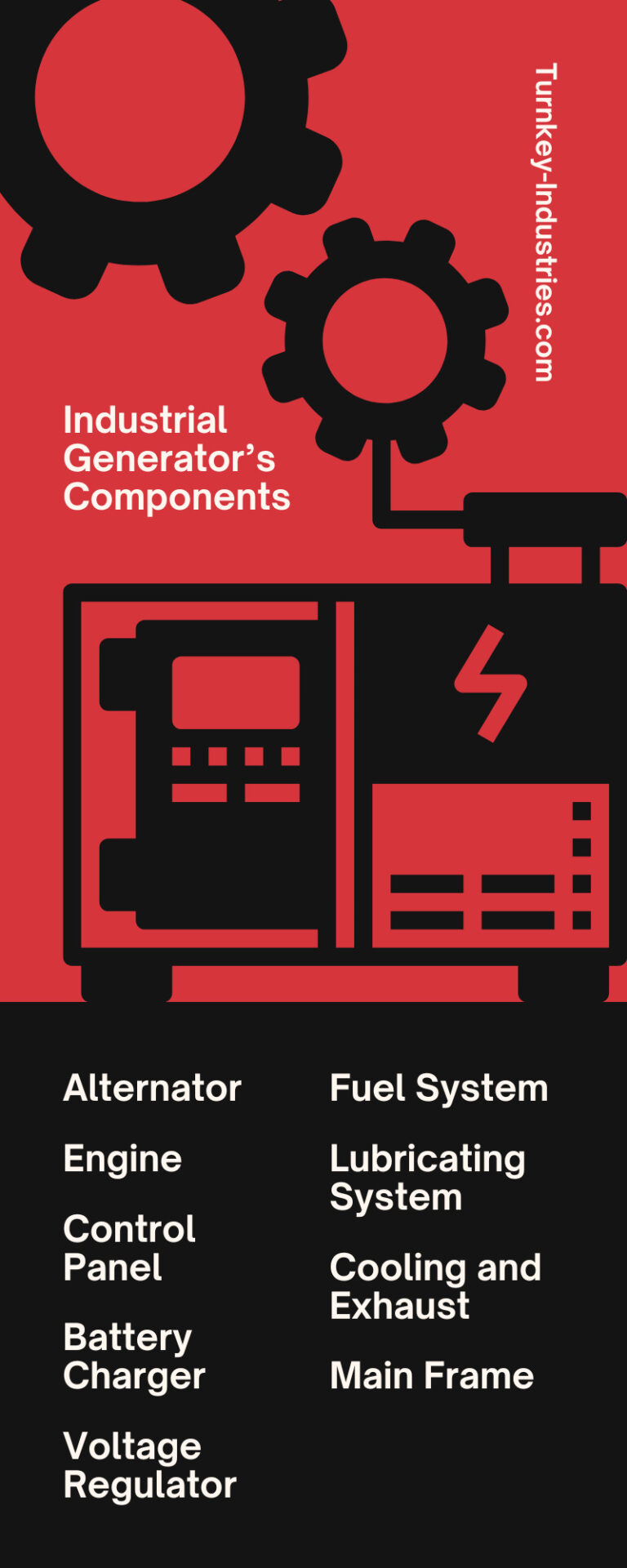

What Are an Industrial Generator’s Components?

To help you gain a better understanding of how an industrial generator operates, let’s take a closer look at all its crucial components and review their operations:

Alternator

Also known as the “genhead,” an alternator is where the conversion from mechanical energy to electrical energy occurs. An alternator has stationary and moving components within its mechanism that are responsible for electron movement production.

Engine

The engine is the generator’s energy hub; this component relies on fuel sources like diesel, gasoline, natural gas, or propane to facilitate energy conversion. The larger the engine in a generator, the more power it can distribute throughout the unit.

Control Panel

A control panel is the generator’s central hub that manages every element of its operation. Control panels may include different features depending on the generator’s model. Additional features may include phase selector switches, engine and generator gauges, and engine control switches.

Battery Charger

While a reliable fuel source is central to a generator’s function, these units require battery power to initiate the operation. A battery charger ensures batteries receive adequate float voltage to maintain the charge while a power unit works.

Voltage Regulator

The voltage regulator controls the voltage of electricity created during its generation. This device also facilitates the conversion of an alternating current (AC) to a direct current (DC) when required.

Fuel System

A generator’s fuel system includes a tank capable of storing up to eight hours of fuel supply. The system also contains a fuel pump responsible for delivering fuel from the tank to the engine. This pipe also connects to a return pipe that returns excess fuel to the tank.

Lubricating System

An industrial generator’s lubricating system has and distributes engine oil to promote a smooth operation. Without the help of this system, standby generator units may experience premature wear affecting all moving parts, cutting a generator’s service life short.

Cooling and Exhaust

The cooling and exhaust systems in an industrial generator are responsible for regulating the unit’s temperature while in operation. The exhaust system also helps dispose of toxic fumes that can otherwise damage the generator’s internal components.

Main Frame

An industrial generator’s main frame provides structure and serves as the foundation to protect all internal components. If it becomes damaged and systems become exposed, your generator can collect debris that may sabotage its functionality.

How Do They Work Together?

While an industrial generator’s components have individual functionalities, they create a comprehensive system that facilitates energy production and distribution when working in conjunction with one another.

While the engine creates mechanical energy, the generator’s voltage regulator partners with the alternator to conduct a four-step cycle until reaching maximum power output.

First Step

First, the unit’s voltage regulator uses a minor quantity of AC voltage and converts it to DC before delivering it to the stator’s secondary exciter windings.

Second Step

In this phase, the secondary exciter windings mimic the primary stator windings and generate additional AC voltage. The secondary windings then create a connection with rotating rectifiers, sending more DC voltage to the generator’s rotor.

Third Step

Here, the rotor induces higher AC voltage across all windings, producing more for the generator.

Fourth Step

As the fourth and final step, the currents continue to move throughout the rotor’s magnetic field, creating an electromagnetic force. The cycle continues until it can convert enough energy to reach an industrial generator’s maximum power capacity.

As the power increases, the unit’s voltage regulator produces less DC voltage but maintains a specific level to keep the equipment running at capacity.

Once the generator’s maximum output decreases, the cycle restarts to accommodate additional loads. This process continues until the equipment shuts down or runs out of fuel.

What Are Turbine-Driven Generators?

In a turbine generator, fluids, steam, gas, or air push through blades on a rotor shaft. The material’s force allows blades to spin, rotating the rotor shaft within the unit.

In turn, the generator converts mechanical energy to electrical energy. While there are different types of turbines, the most common in an industrial setting are combustion turbines that utilize fuel.

Industrial generators are fascinating machines with complex mechanisms. When working together, these components allow industrial generators to create electricity to provide continuous energy to a facility.

Turnkey Industries is a trusted expert in industrial and commercial generators. Our team of professionals purchases, sells, services, and tests power units to ensure functionality.

We conduct rigorous vetting practices to determine efficient equipment for our customers. For more information, please complete a contact form on our webpage, and our team will promptly assist you.

Turnkey Industries offers a variety of high-capacity

Turnkey Industries offers a variety of high-capacity